Delivering the highest quality Auto Parts and EV parts, trusted by global brands.

US-Based Auto Parts Manufacturing, Chosen by Global Automotive Leaders

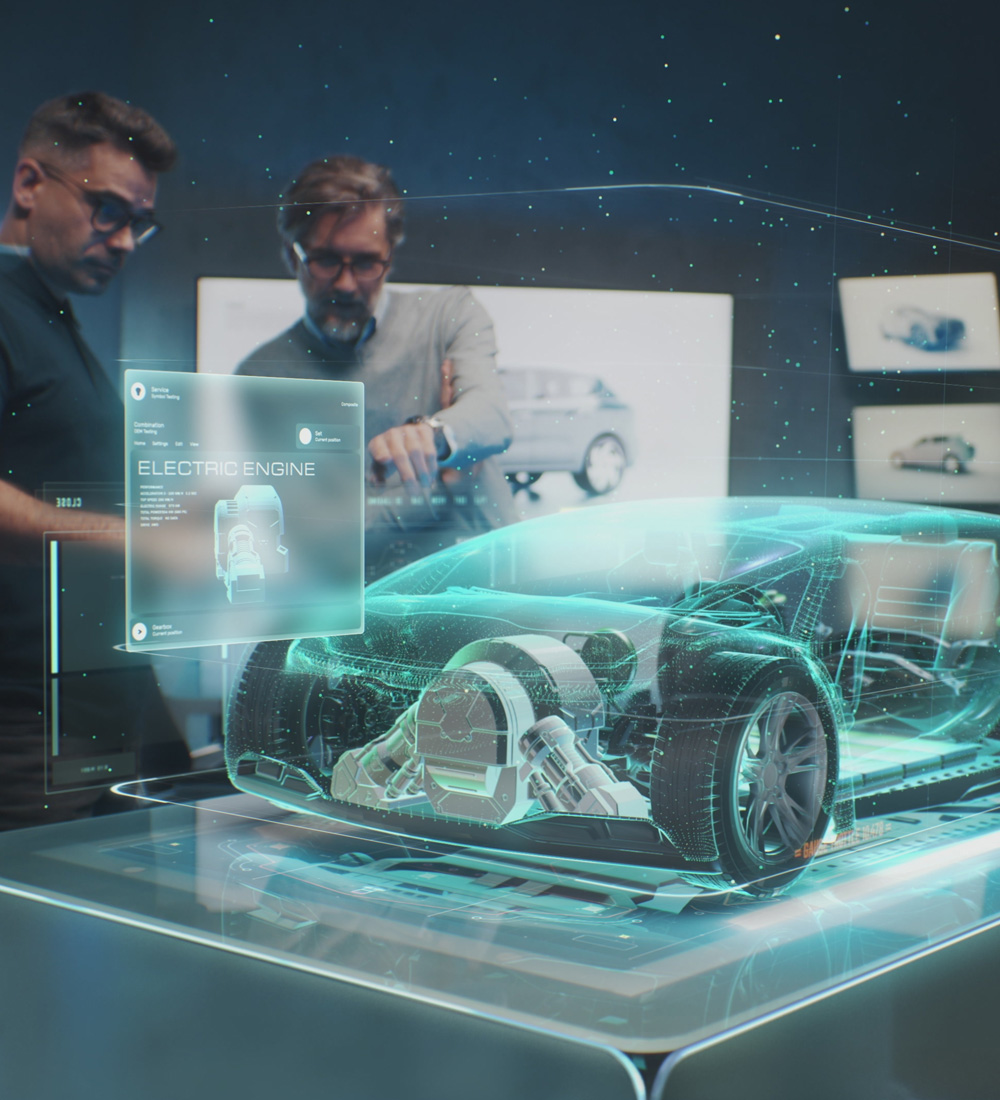

Shinhwa Auto USA is more than a parts manufacturer; we are a technology solutions partner dedicated to transforming your most ambitious designs into flawless reality.

Global Production Capacity

Technology-Driven Solutions

Intelligent Quoting & Analysis

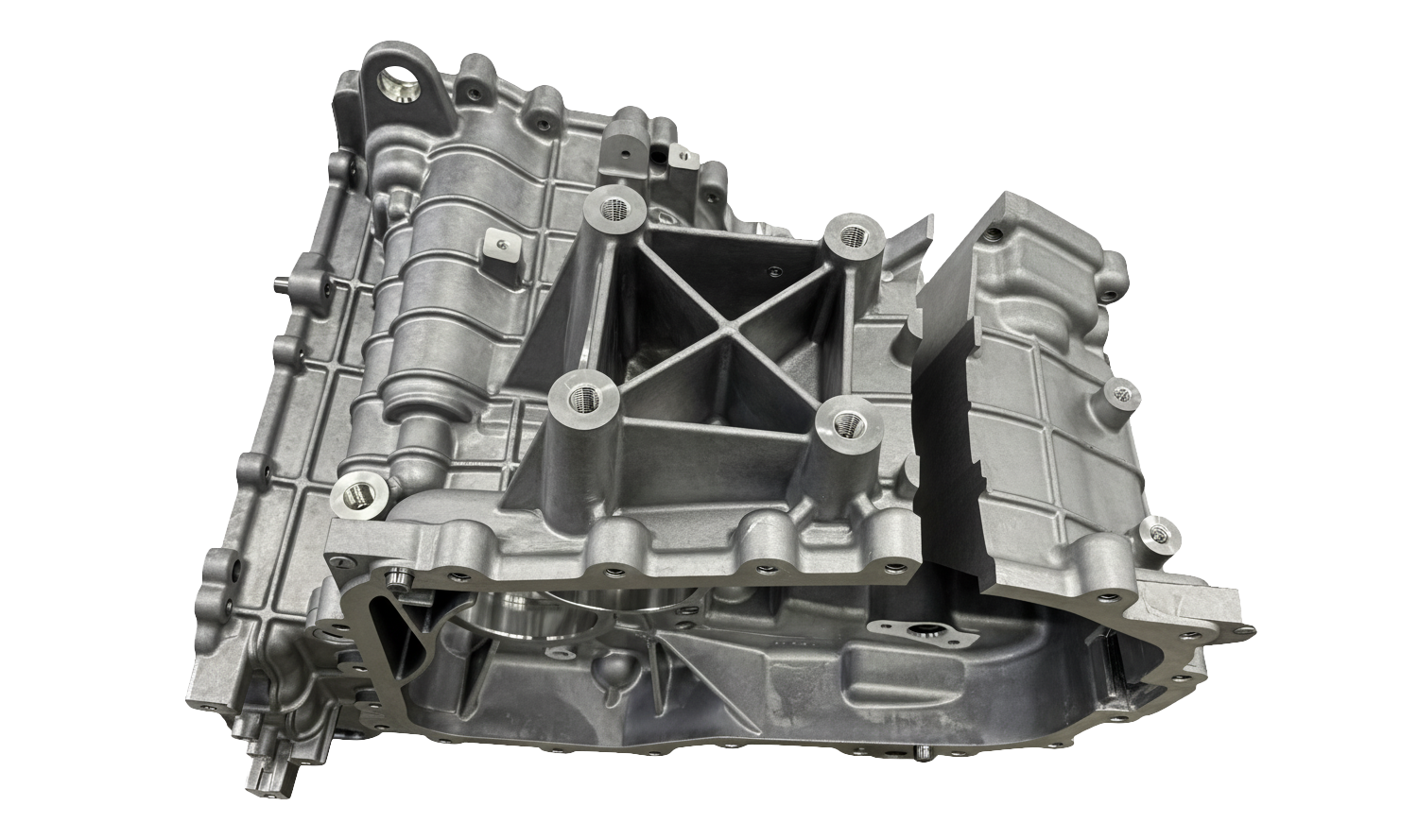

Our Products

E-Mobility Powertrain & Power Systems

Motor Housing

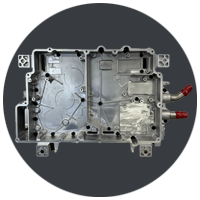

Integrated Charging Control Unit (ICCU)

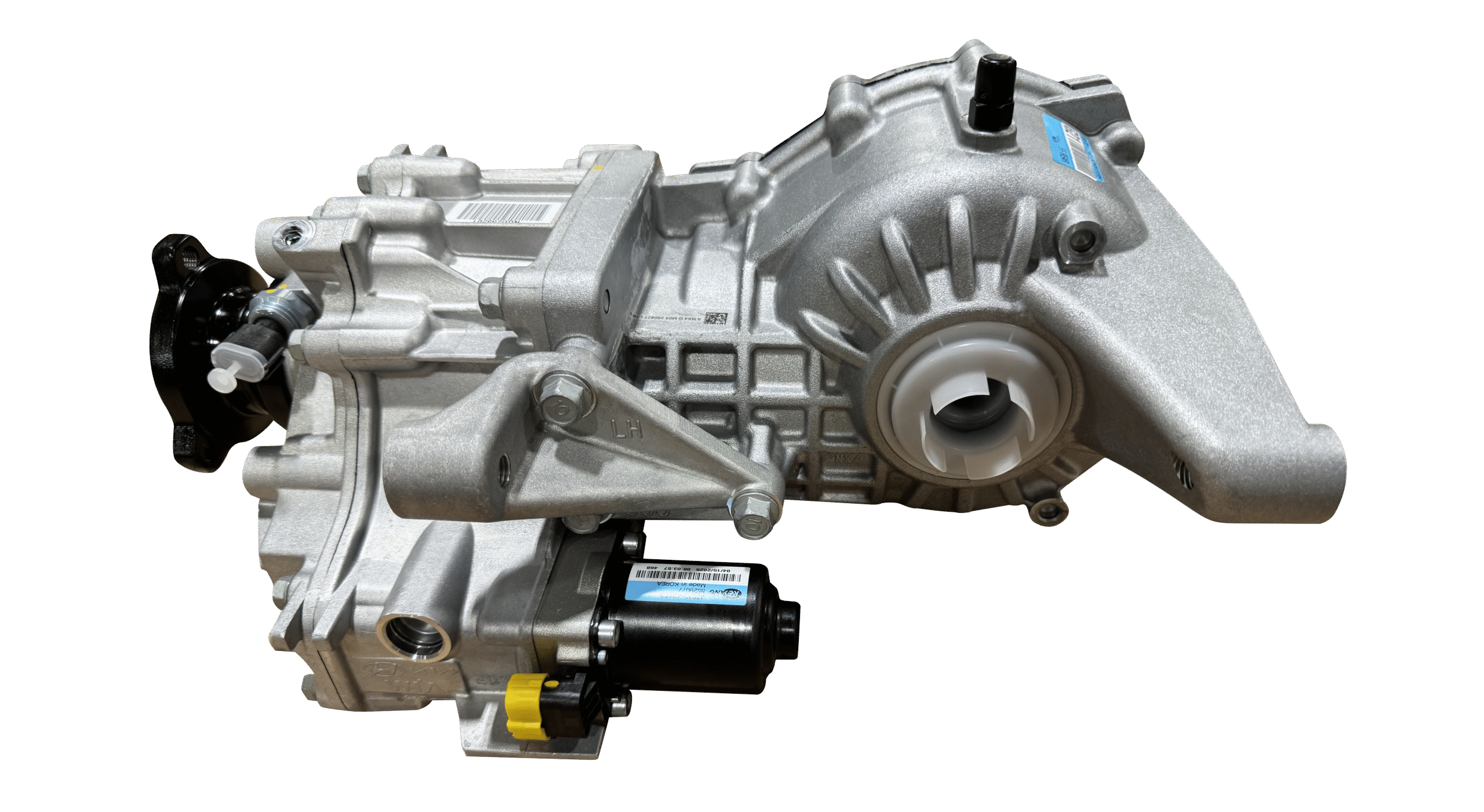

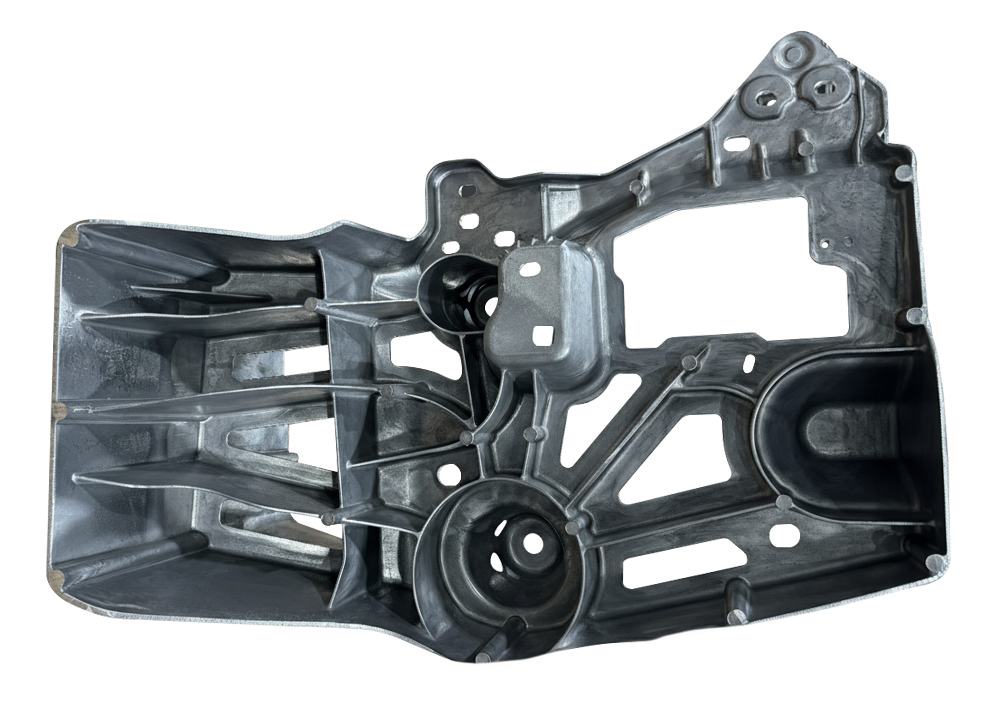

Drivetrain & Driveline Components

Axle

Pinion

Differential Cover

Tripod Joint (TJ)

Gear

Differential Carrier

Birfield Joint (BJ)

Drive Shaft

Chassis & Structural/Safety Components

Tailgate Tower

Knuckle

Bracket

Rear Bumper Beam

Carrier

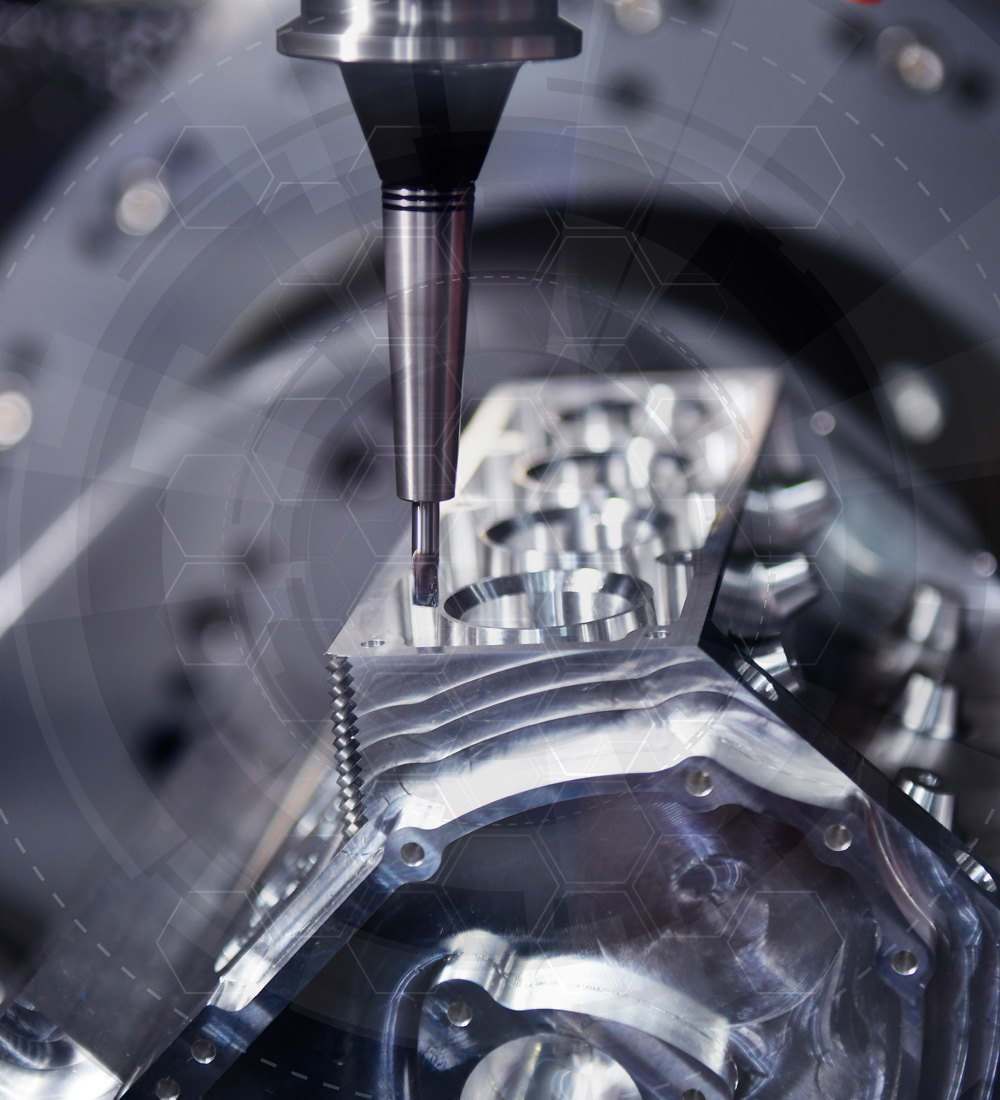

Great Ideas, Made Perfect. At Scale. That’s the Manufacturing Difference.

Engineering the Heart of All Mobility

Key Capabilities:

- Production of high-efficiency internal combustion components

- Specialization in next-generation E-mobility solutions

- Comprehensive technology for all vehicle platforms

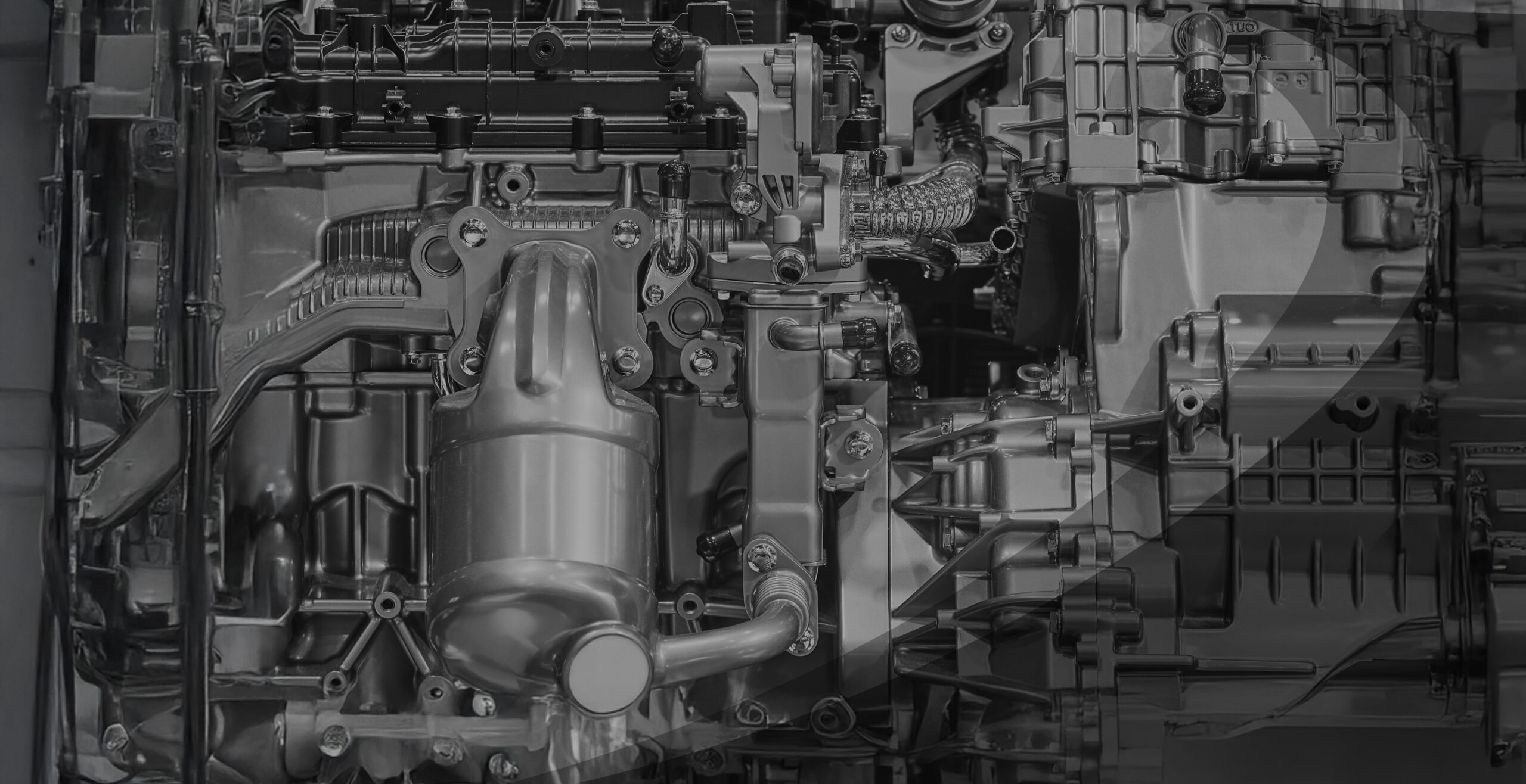

Powertrains for Today & Tomorrow

Key Capabilities:

- The stability of proven internal combustion technology

- A technology roadmap for the transition to E-mobility

- Long-term, forward-looking technology partnerships

Engineering for Every Generation of Powertrain.

Key Capabilities:

- In-depth knowledge of diverse power sources

- Precision solutions for any technical specification

- Technological continuity secured by ongoing R&D

We deliver proven solutions for the industry’s toughest demands.

Challenge: EV Performance Limits

Our Solution: Advanced Lightweighting Tech

Reliability, Guaranteed by Technology: Eliminate supply chain uncertainty with a proven quality system trusted by Hyundai and Tesla

Accelerate Your Timeline: Launch new products faster with our one-stop, vertically integrated manufacturing solution.

Co-Engineer for Success: Reduce costs and maximize performance by partnering with our engineering experts from day one.

Why SHINHWA? Your Advantage for a Successful Launch

Engineered Solutions for Every Application