Facility & Equipment

Advanced Manufacturing for Large-Scale Production

Everything About Shinhwa Auto’s North America Smart Factory

Shinhwa Auto’s 356,000 sq.ft. (approx. 33,000 m²) facility in Auburn, Alabama goes beyond being a factory—it is a strategic asset designed for efficiency, scalability, and unmatched quality.

As a state-of-the-art Smart Factory, every piece of equipment is part of an integrated digital ecosystem managed by a next-generation MES (Manufacturing Execution System). This ensures maximum control, real-time monitoring, and data-driven optimization at every stage of production, allowing us to meet and exceed the expectations of our global partners.

Our In-House Capabilities: A Tour of Our Equipment

We have made significant investments in world-class equipment to control every core manufacturing process internally.

Our process begins with premium raw materials and powerful, precision-controlled casting cells capable of handling a wide range of component sizes and complexities.

-

Melting Furnaces: 3 large-capacity operating units

-

High-Pressure Die Casting (HPDC) Machines:

-

CPC (Complex Pressure Casting) Lines: 5 advanced lines

-

LPDC (Low-Pressure Die Casting) Lines: 10 dedicated lines for high-integrity structural components

Your Advantage: This extensive and diverse casting capability allows us to handle everything from small, intricate components to large, robust structural parts—backed by ample capacity and redundancy to support even the highest production volumes without disruption.

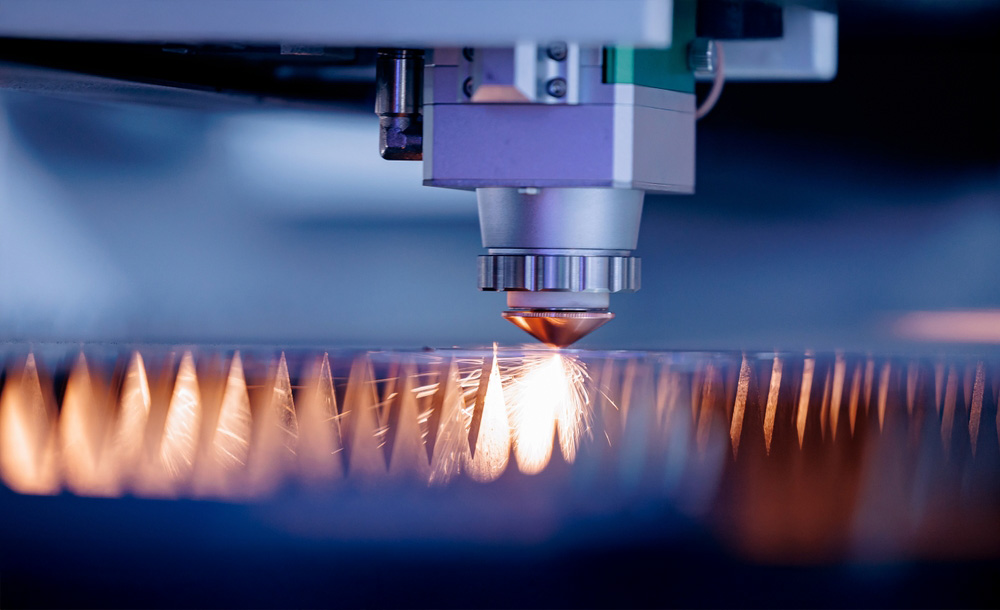

Our facility is equipped with a wide range of automated machining centers, designed to consistently achieve sub-micron tolerances.

-

CNC Machines: 100+ high-speed machining centers

-

Machining Automation Systems: 44 integrated robotic systems for automated loading, unloading, and inline transfer

Your Advantage: This high level of automation ensures outstanding part-to-part consistency, reduces the possibility of human error, and delivers the extreme precision required for critical applications—at competitive cost and high throughput.

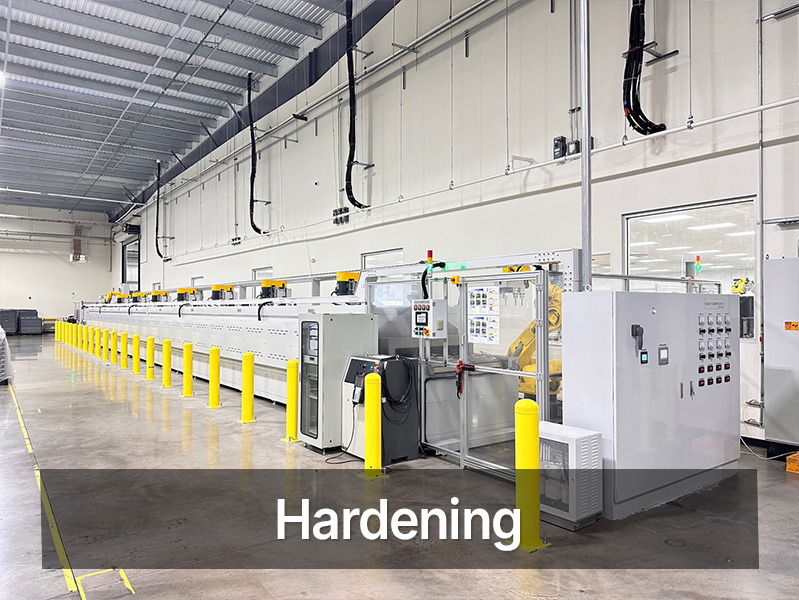

We manage the final metallurgical properties and surface preparation of parts through comprehensive in-house processes.

-

Heat Treatment Furnaces:

-

3 batch-type

-

1 continuous-type for precise T6 and other heat-treatment cycles

-

-

In-house Capabilities: Dedicated lines for carburizing, painting, and complex assembly

Your Advantage: Our in-house finishing capabilities streamline the entire production process, shorten lead times, and provide more complete, installation-ready parts from a single accountable source.

To validate our zero-defect promise, we have invested in one of the industry’s most advanced suites of metrology and inspection equipment.

-

X-Ray ADR (Automatic Defect Recognition): 4 powerful units for 100% non-destructive internal inspection

-

PT (Penetrant Testing) Line: 1 dedicated line for surface crack detection

-

Advanced Metrology: Fully equipped labs with CT scanners for 3D analysis and multiple CMMs (Coordinate Measuring Machines) for dimensional validation

Your Advantage: We don’t just inspect surfaces—we validate the internal structural integrity of every critical component. This ensures reliability, safety, and complete data-backed confidence in every part we deliver.

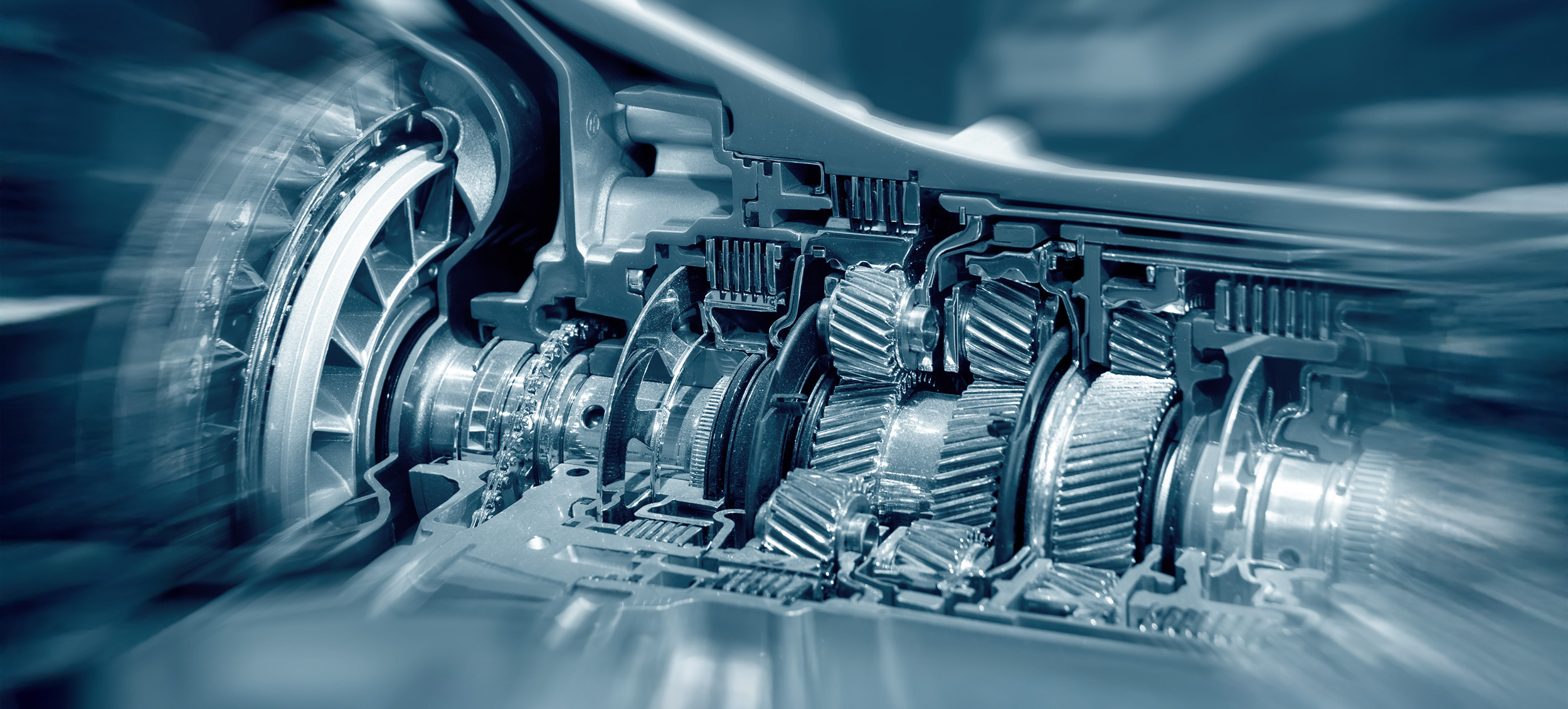

Precision for Future Mobility: Shinhwa Auto USA’s Advanced Production Line

Shinhwa Auto USA’s production line is more than just a collection of manufacturing facilities; it is the heart of a futuristic smart factory, combining innovative technology with complete automation. We vertically integrate every process from digital design to final validation, producing the highest quality automotive components with a ‘zero defect’ philosophy through state-of-the-art equipment and an intelligent MES (Manufacturing Execution System).

This equipment list is not static. Ongoing investments—such as new CPC lines and additional machining automation—signal Shinhwa Auto’s unwavering commitment to growth, innovation, and partnership. We continuously expand our capabilities and upgrade technologies to grow with our partners and prepare for the challenges of the future.

Our core competencies are rooted in advanced aluminum die-casting technology, ultra-precision machining know-how, and future-oriented research and development. Leveraging these integrated capabilities, we consistently meet our clients’ most complex and demanding requirements, reliably supplying high-performance, lightweight, and highly efficient core components. Shinhwa Auto is ready to turn your vision into reality, help you gain a competitive edge, and collectively usher in the era of sustainable future mobility.