R&D and Co-Engineering

Engineering Tomorrow, Together. Your R&D Partner for Next-Generation Mobility

At Shinhwa Auto USA, Research & Development is not a back-office function; it is a collaborative service we provide to our partners. We believe the most groundbreaking innovations happen when a customer’s design vision meets deep manufacturing expertise. That’s why we function as an extension of your own R&D and engineering teams, bringing our knowledge of materials, casting physics, and process optimization to the earliest stages of your project. Our goal is simple: to help you solve your toughest challenges and launch better products, faster.

From Concept to Perfection

We have developed a structured, collaborative process to ensure your design is optimized for performance, cost, and manufacturability from day one.

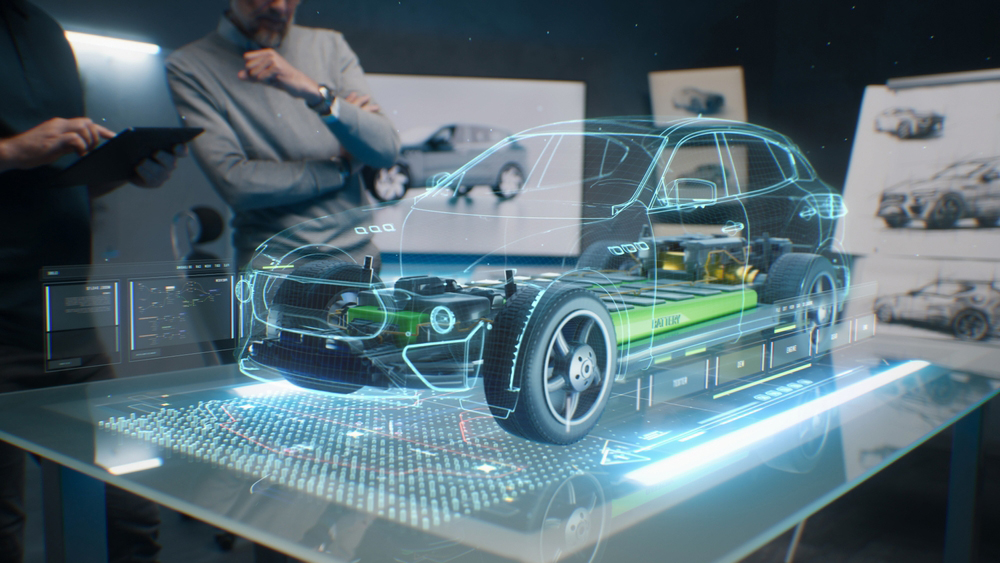

Using state-of-the-art software, we run comprehensive casting flow, thermal, and structural simulations.

This “digital twin” approach allows us to perfect your part in the virtual world first, providing critical Design for Manufacturability (DFM) feedback.

- Your Advantage: This digital-first process identifies and resolves potential manufacturing issues before any physical tooling is made, saving you significant time and cost in development and avoiding expensive post-production changes.

We engage with your team at the initial concept phase to understand your goals, challenges, and performance targets.

This allows us to provide valuable insights before critical design decisions are locked in.

We leverage our integrated capabilities to rapidly produce and validate prototypes.

Our in-house testing facilities ensure that the physical part performs exactly as the digital simulations predicted.

Our R&D process doesn’t end at launch.

Through our MES system, we gather mass production data and feed it back into our R&D loop. This allows us to continuously refine processes and inform the design of your next-generation products.

Key R&D Focus Areas

Our R&D efforts are focused on solving the most critical challenges facing the automotive industry today.

Next-Generation Materials

We are at the forefront of developing and rigorously testing new lightweight aluminum alloys. Our research focuses on innovatively increasing strength-to-weight ratios, exceptionally enhancing thermal properties, and maximizing the overall performance and efficiency of critical automotive components.

Your Advantage: Our materials expertise allows you to design vehicles with longer EV range, superior handling dynamics, and enhanced crash safety performance.

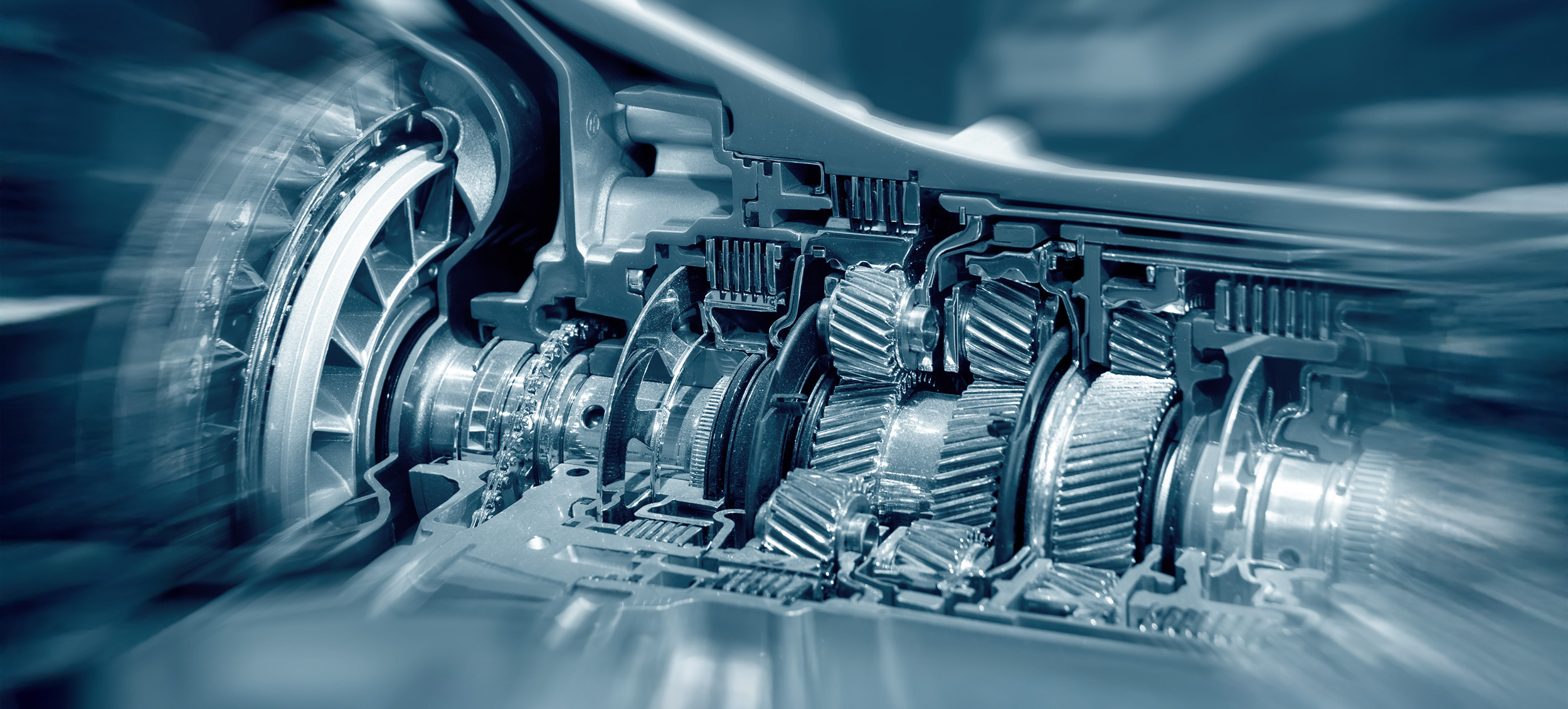

Advanced Casting & Mold Design

We are constantly pushing the boundaries of what is possible with casting technology. Our R&D in smart mold design, complex cooling channels, and defect-free casting techniques enables the production of highly integrated, monolithic components that were previously impossible.

Your Advantage: You can consolidate multiple smaller parts into a single, stronger, and lighter casting, which simplifies your assembly process and improves overall vehicle integrity.

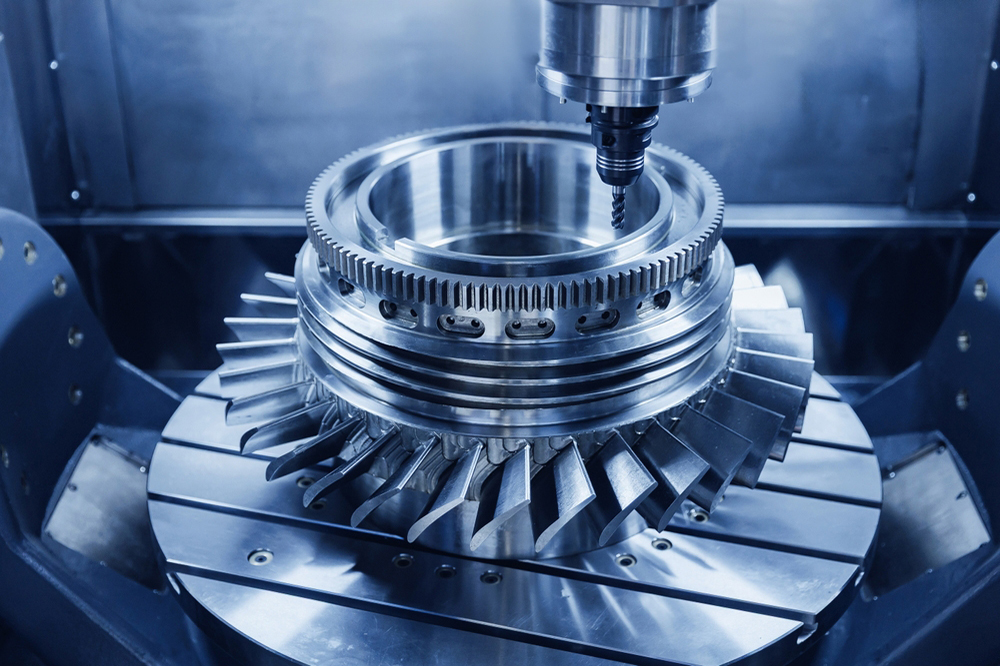

Digital Manufacturing & Process Simulation

We invest heavily in the digital tools that give us—and you—a competitive edge. Our expertise in simulating the entire manufacturing process ensures predictability, consistency, and a higher level of quality control from the very first part to the millionth.

Your Advantage: This removes guesswork from the manufacturing process, resulting in faster launch times, lower scrap rates, and the confidence that your part will meet spec every time.

Innovating Future Mobility, Starting with Shinhwa Auto USA’s R&D Partnership

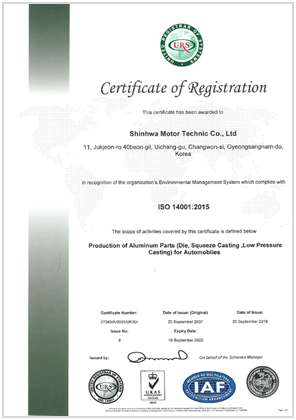

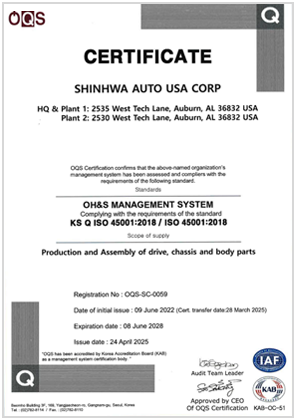

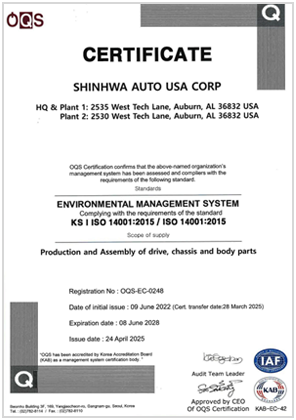

Key Quality Certifications

Shinhwa Auto demonstrates our exceptional quality capabilities through internationally recognized quality management system certifications.

ISO-9001

IATF16949 Certificate

ISO 14001 Certificate

IATF16949 Certificate

ISO 14001 Certificate

SQ CERTIFICATION

ISO 45001

ISO 14001

Visible Tech, Invisible Perfection, and Data-Driven Zero-Defect Manufacturing.

Our core competencies are rooted in advanced aluminum die-casting technology, ultra-precision machining know-how, and future-oriented research and development. Leveraging these integrated capabilities, we consistently meet our clients’ most complex and demanding requirements, reliably supplying high-performance, lightweight, and highly efficient core components. Shinhwa Auto is ready to turn your vision into reality, help you gain a competitive edge, and collectively usher in the era of sustainable future mobility.