The Start of Precision Power Distribution

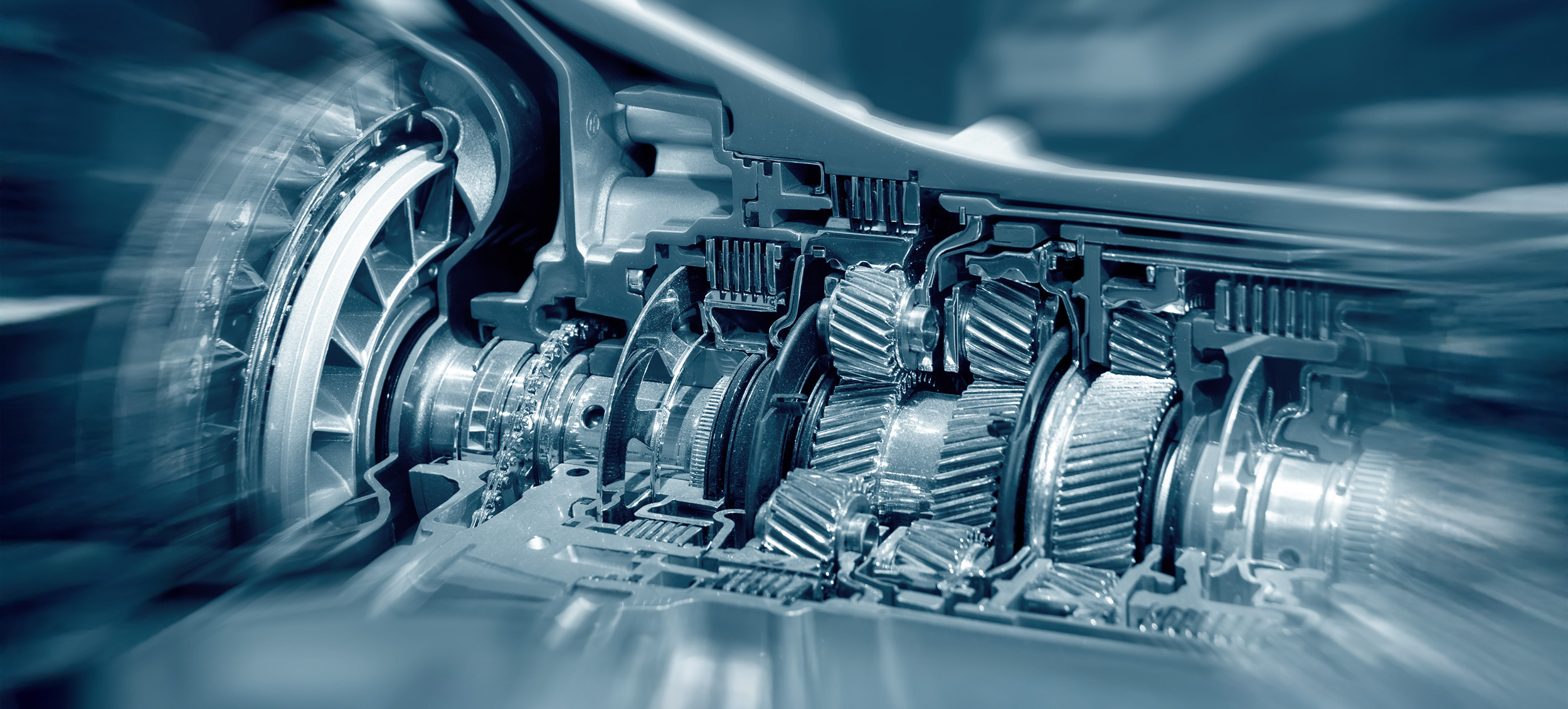

Shinhwa Auto’s Differential Carrier is one of the most crucial structural components in a vehicle’s powertrain, playing an essential role in robustly fixing and supporting the differential gear set to optimally distribute power to each wheel. Especially during turns, it precisely compensates for the difference in rotational speeds between the left and right wheels, thereby ensuring stable vehicle steering and optimal traction.

We combine high-strength lightweight aluminum die-casting technology with micrometer-level ultra-precision machining capabilities to provide the core foundation for high-performance, high-efficiency drive systems required by future electric and autonomous vehicles.

Fixes and supports the differential gears.

Transmits rotational force via the ring gear.

Mounts side gears and pinion gears internally.

Shinhwa Auto meets customers’ most demanding requirements through technological leadership and innovation in differential carrier manufacturing. We promise to contribute to customer success and the advancement of future mobility by providing products with the highest quality, performance, and reliability.