Turning the Most Complex Designs into Flawless Reality

Shinhwa Auto’s competitive advantage is rooted in our comprehensive, in-house technological capabilities. We are not just a provider of services; we are a true, vertically integrated manufacturing partner. This means we command absolute control over every critical process variable, from the initial casting of molten metal to the final precision assembly. For our partners, this translates into unmatched quality, accelerated development and production timelines, reduced risk, and a single, accountable point of contact throughout the entire product lifecycle.

Our Integrated Technology Ecosystem

We have invested in a complete ecosystem of advanced technologies to provide a genuine one-stop solution for the most demanding automotive components.

Shinhwa Auto possesses leading die-casting technologies to meet diverse requirements.

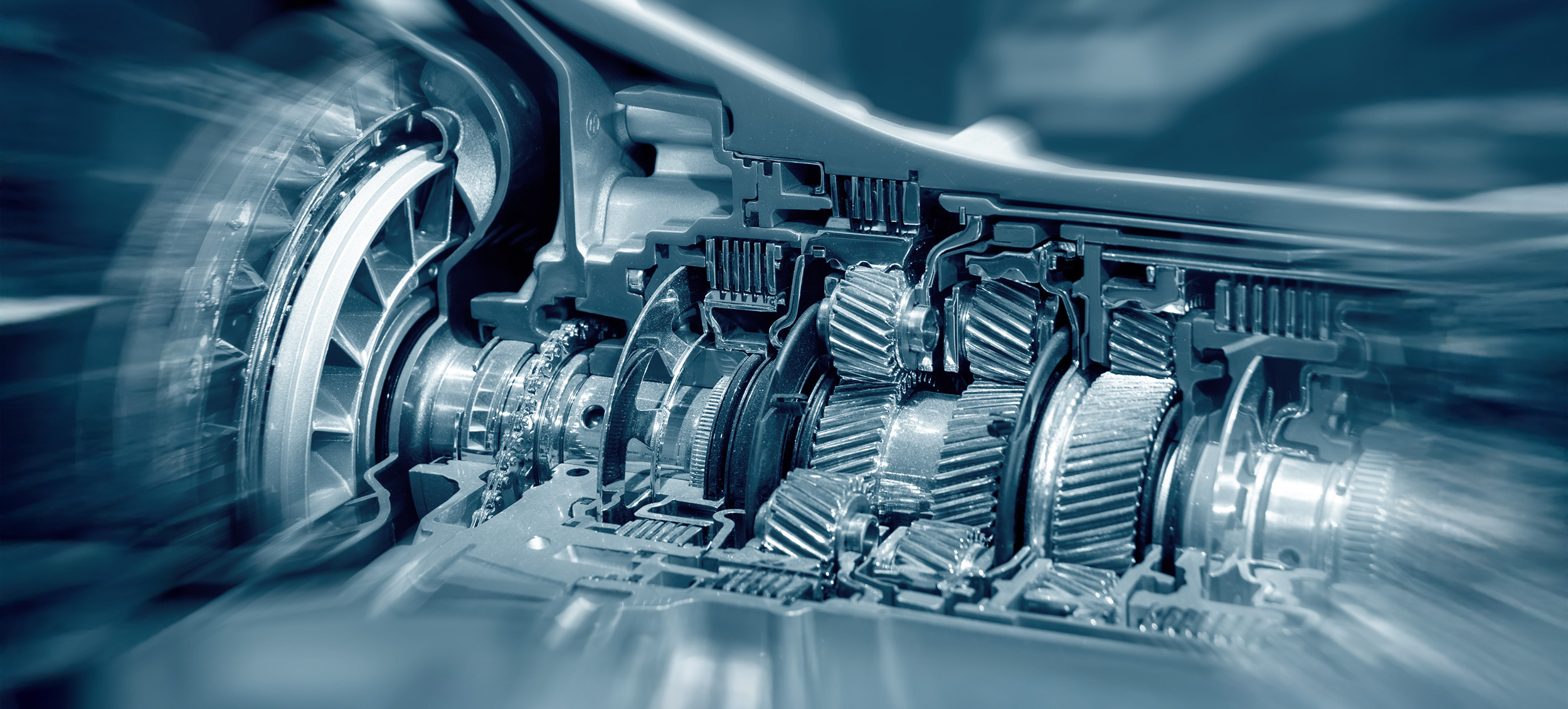

High-Pressure Die Casting (HPDC)

- Primary Applications: Complex EV motor housings, transmission cases, electronic enclosures.

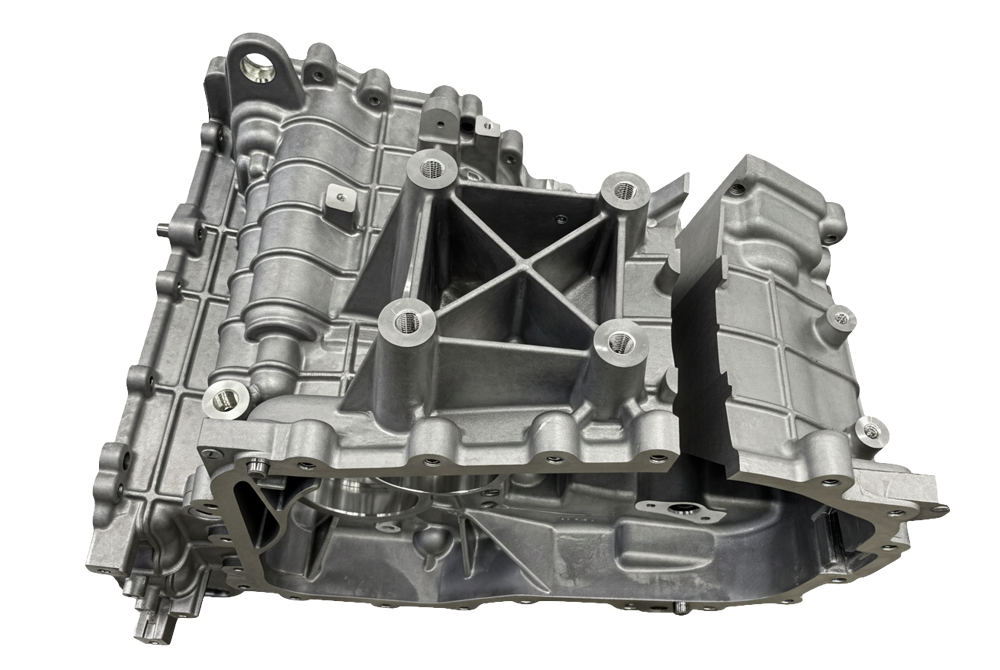

Complex & Low-Pressure Die Casting (CPC/LPDC)

- Primary Applications: Battery enclosures, shock towers, subframes, and other safety-critical chassis parts.

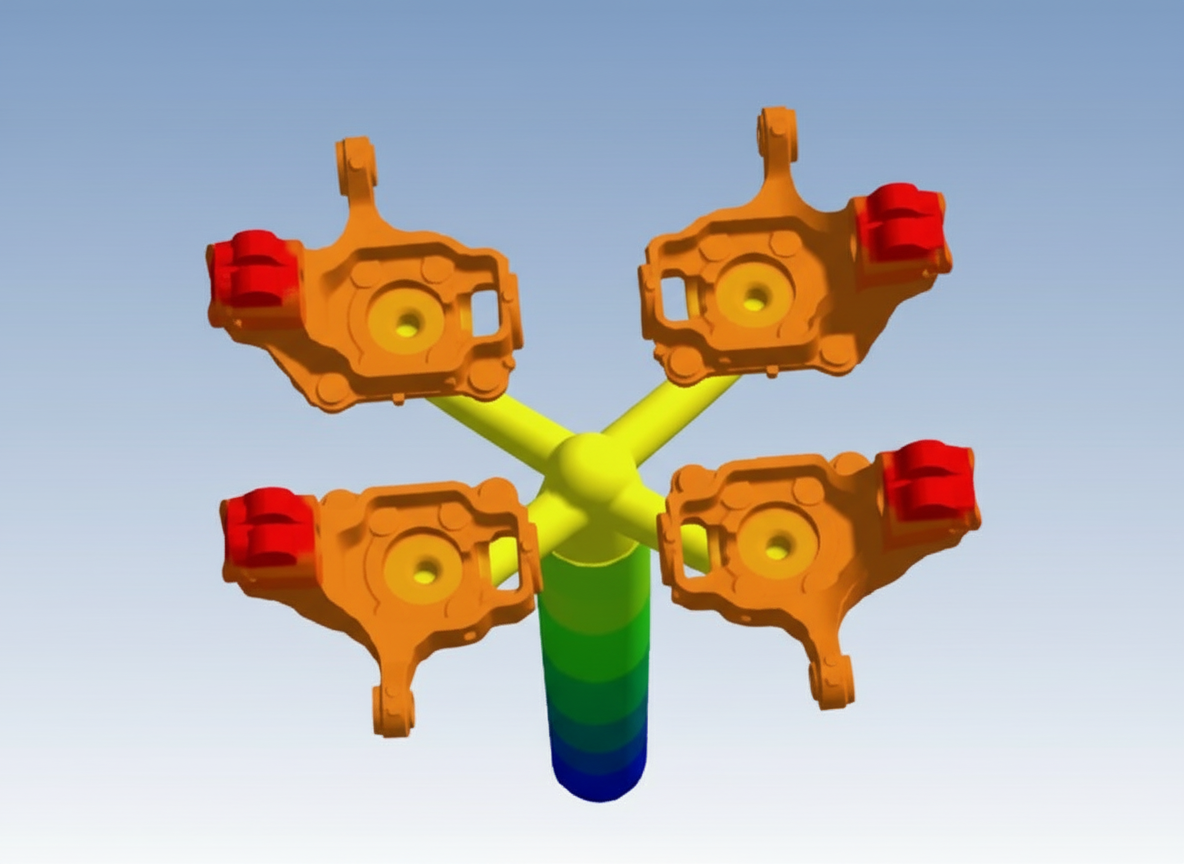

Innovation in Shinhwa Low-Pressure Casting Technology

- Method Features: Achieves uniform quality through a multi-cavity system (configurable 4-6 cavities) and precise control of the low-pressure liquid metal feeding device.

- Cavity & Productivity: The multi-cavity (4-cavity) system boasts approximately 5 times higher productivity than conventional methods, enabling the production of 51 parts per hour.

- Cooling Method: Employs a mist (water + air) cooling method, ensuring excellent cooling effects, directional solidification, and refined microstructure through reduced CT (cooling time) to maximize component strength and durability.

- Application Cases: Proven excellence through participation in national projects (“Development of AL Knuckle for Semi-Midsize Cars Using Multi Cavity Low Pressure Casting”) and successful mass production and long-term supply of FAGOR (Spain) GM DELTA J300 / 309 Knuckles.

- In-house Design Capabilities: Possesses proprietary product and mold design capabilities for core components such as knuckles and control arms.

Low-Pressure Casting

Our machining technologies deliver unparalleled precision and reliability.

Automated CNC Machining

Complete Gear Solutions

We directly control all final stages that determine a component’s ultimate performance and readiness for use.

In-house Heat Treatment (T6 & Carburizing)

Assembly & Painting

Integrating such diverse advanced technologies under one roof creates powerful synergies beyond mere convenience.

Our core competencies are rooted in advanced aluminum die-casting technology, ultra-precision machining know-how, and future-oriented research and development. Leveraging these integrated capabilities, we consistently meet our clients’ most complex and demanding requirements, reliably supplying high-performance, lightweight, and highly efficient core components. Shinhwa Auto is ready to turn your vision into reality, help you gain a competitive edge, and collectively usher in the era of sustainable future mobility.