From Digital Design to Flawless Delivery

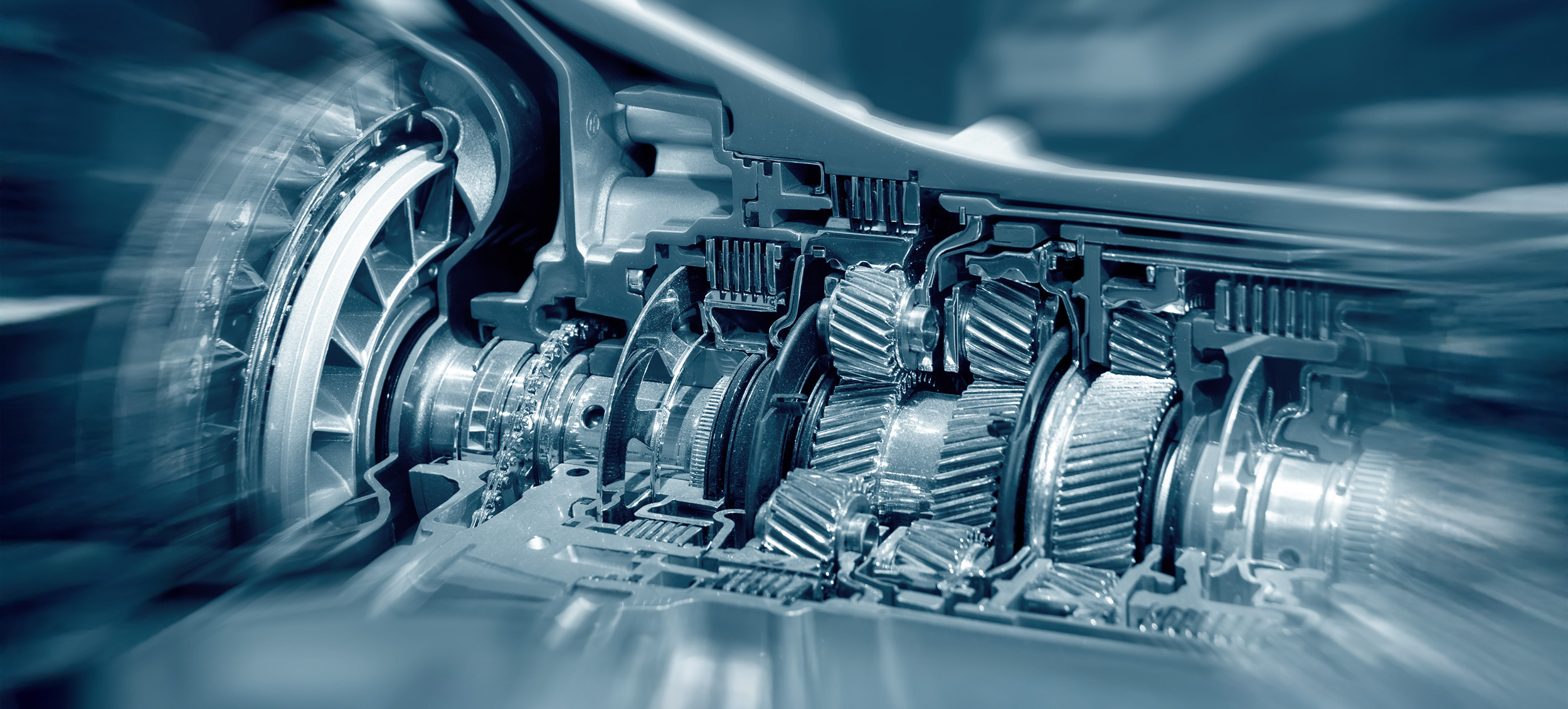

At Shinhwa Auto USA, manufacturing is not a series of separate steps; it is a single, cohesive ecosystem designed for perfection.

We have mastered and integrated every critical stage of production under one roof—from initial design simulation to final validation and shipment. This vertical integration, powered by a state-of-the-art MES (Manufacturing Execution System), creates a “digital thread” that follows every component. This ensures that every part we produce is tracked, controlled, and optimized for world-class quality and on-time delivery.

Our Step-by-Step Path to Perfection

This is how we transform your complex designs into precision-engineered reality.

Step 1: Co-Engineering & Digital Simulation

Step 2: Precision Casting (HPDC, CPC, LPDC)

Step 3: Ultra-Precision Machining

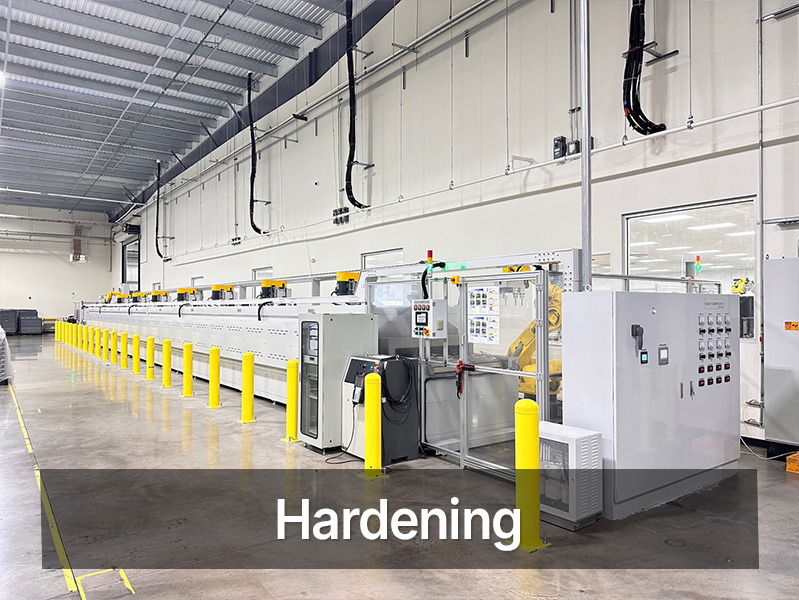

Step 4: Specialized Heat Treatment

Step 5: Assembly, Finishing & Testing

Step 6: Rigorous Final Validation

The Digital Backbone: Our Smart Factory System

Shinhwa Auto USA’s Integrated Manufacturing Process Promises Perfection

Key Advantages of Shinhwa Auto USA’s Manufacturing Process:

- Ultimate Precision: Sub-micron tolerance control ensures perfect part consistency and fit during assembly.

- Cost Efficiency: Reduced development costs and minimized waste through Design for Manufacturability (DFM) optimization.

- Unwavering Reliability: Stringent quality control at every stage and thorough final validation via X-Ray and CT scanners.

- Prompt Delivery: Automated processes and real-time monitoring ensure fast and accurate adherence to production schedules.

With Shinhwa Auto USA, your most complex requirements can be realized with perfect quality and efficiency. Experience Shinhwa Auto USA’s manufacturing innovation today and lead your next project to success.

Precision for Future Mobility: Shinhwa Auto USA’s Advanced Production Line

Shinhwa Auto USA’s production line is more than just a collection of manufacturing facilities; it is the heart of a futuristic smart factory, combining innovative technology with complete automation. We vertically integrate every process from digital design to final validation, producing the highest quality automotive components with a ‘zero defect’ philosophy through state-of-the-art equipment and an intelligent MES (Manufacturing Execution System).

Our core competencies are rooted in advanced aluminum die-casting technology, ultra-precision machining know-how, and future-oriented research and development. Leveraging these integrated capabilities, we consistently meet our clients’ most complex and demanding requirements, reliably supplying high-performance, lightweight, and highly efficient core components. Shinhwa Auto is ready to turn your vision into reality, help you gain a competitive edge, and collectively usher in the era of sustainable future mobility.