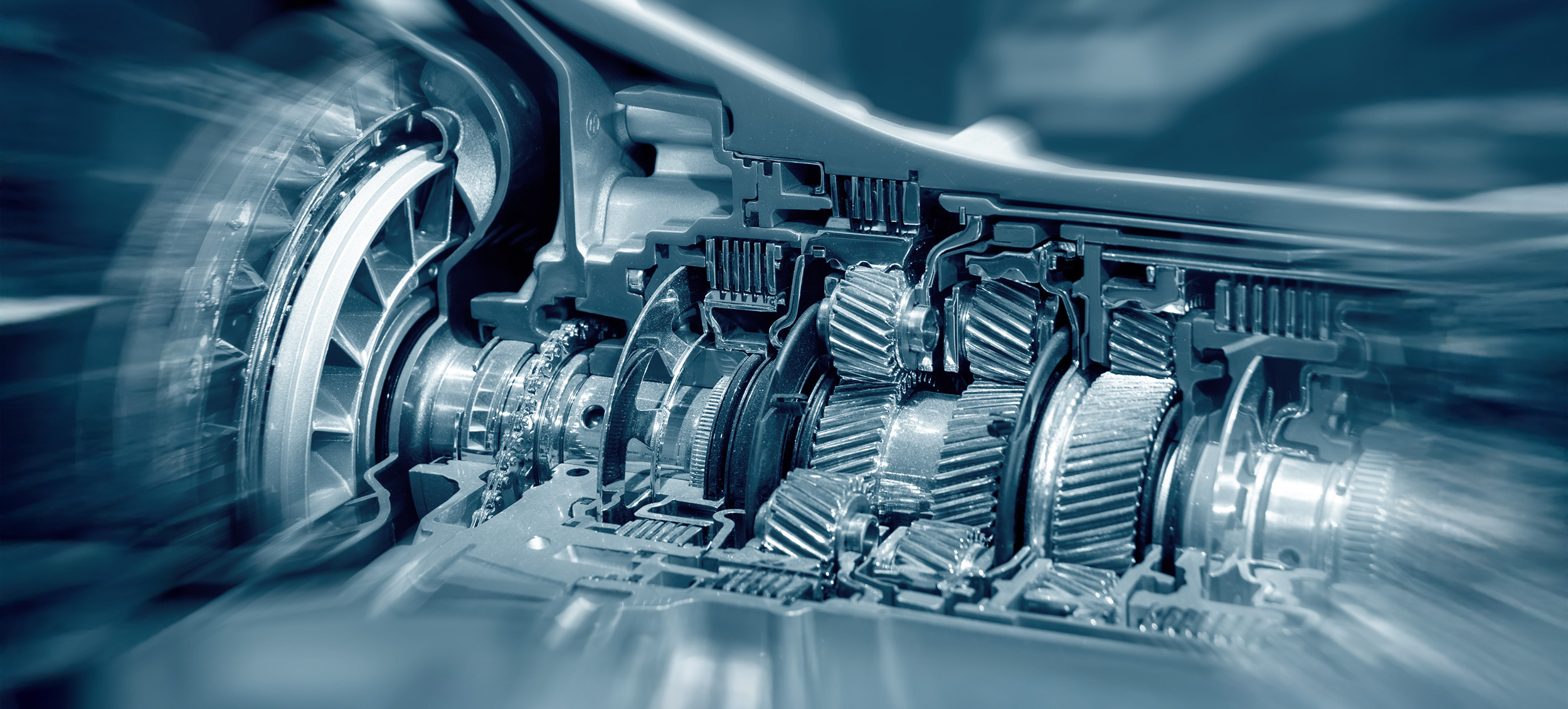

Shinhwa Auto’s Commitment to Quality

At Shinhwa Auto, quality is more than just product specifications; it is our core value and an unwavering promise to our customers. With over 50 years of experience leading the automotive components industry, we firmly uphold the philosophy that quality equals safety and performance.

Quality Inspection and Management Standards

Our quality management system establishes its own highest standards, surpassing international benchmarks such as ISO/TS 16999. This proactive approach aims to meet the increasingly demanding requirements of the future mobility era and provide customers with the utmost trust and satisfaction. Every component from Shinhwa Auto embodies our technological prowess alongside our steadfast commitment to customer safety and success.

Cutting-Edge Quality Verification & Testing

Key Quality Certifications

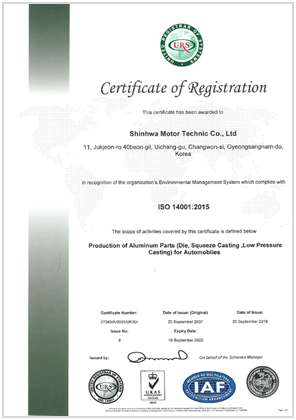

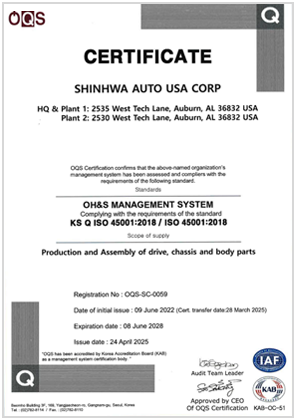

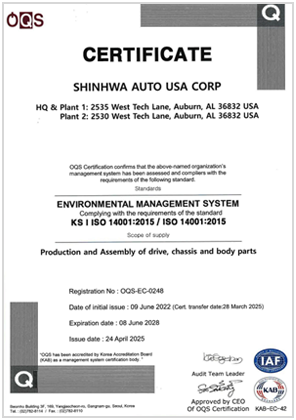

Shinhwa Auto demonstrates our exceptional quality capabilities through internationally recognized quality management system certifications.

- IATF 16949: Quality management system standard for the automotive industry (International Automotive Task Force 16949)

- ISO 9001: General quality management system standard (International Organization for Standardization 9001)

- ISO 14001: Environmental management system standard (International Organization for Standardization 14001)

Ultra-Precision Engineering & Design

Raw Material Quality Control

Smart Manufacturing & Process Control

- Monitors and controls the entire production process in real-time through a smart factory system. Automated production lines and AI-based inspection systems detect even minute defects to maintain perfect quality.

- Utilizes SPC (Statistical Process Control) techniques to minimize process variation and ensure stable production quality.

ISO-9001

IATF16949 Certificate

ISO 14001 Certificate

IATF16949 Certificate

ISO 14001 Certificate

SQ CERTIFICATION

ISO 45001

ISO 14001

Quality Inspection and Management Standards

Quality Inspection Items

| Item | Fixed | Specific | Size / Frequency | Inspection |

|---|---|---|---|---|

| Aluminum Alloy | ASTM B 108 | Chemical Composition - ASTM B 108 | 2/Bundle | Ingredients Analyzer (Dry) |

| Cooling Curve Analysis | 1/Bundle | |||

| Density standard after | GBF after melting | 1/Bundle | ||

| Part | Heat Treatment | Mechanical Properties | 2/Lot | Lot Material Test M/C |

| Structure - 2DAS / Grain Size | 1/Lot | Lot Microscope | ||

| Dimension | 2/Lot | Inspection Gauge CMM | ||

| X-ray | Internal defect - ASTM E 155 | Inside and full area of product | Automatic defect reading | |

| PT TEST | Internal defect ASTM E 155 | Inside and full area of product | PT Inspection M/C | |

| Property Test | Dimensions and Mechanical Properties | Criteria for heat treatment | Inspection Gauge, CMM | |

| Mechanical processing area |

Visible Tech, Invisible Perfection, and Data-Driven Zero-Defect Manufacturing.

Shinhwa Auto contributes to customer success in the crucial field of motor housing for the EV era with innovative technology and the highest level of quality. We provide customized solutions optimized for customer requirements and will elevate the performance and reliability of future mobility to the next level.