Shinhwa Auto USA’s High-Precision Brackets

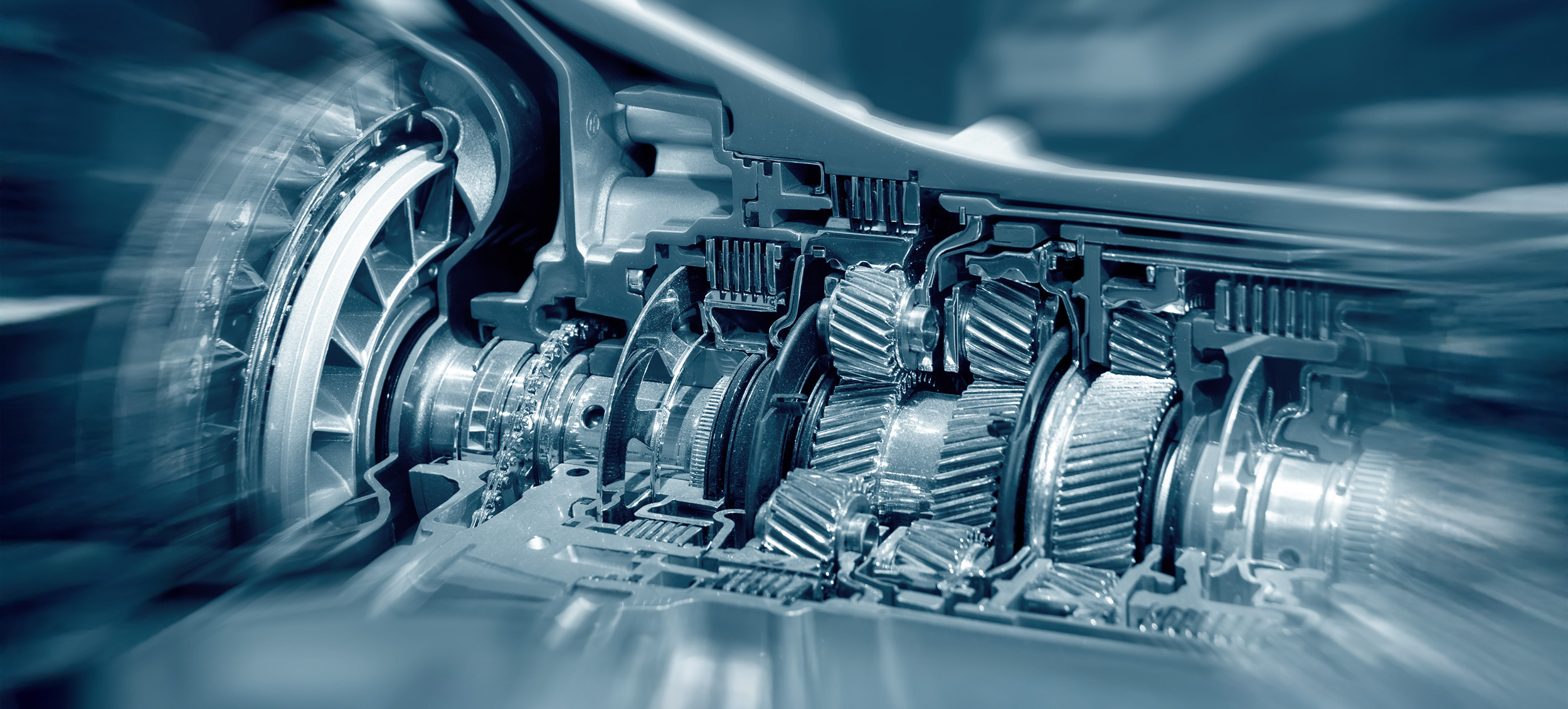

An invisible hero that determines a vehicle’s safety, durability, and performance is the bracket. It firmly supports and connects various critical components such as engines, transmissions, suspensions, and battery packs, ensuring the overall structural integrity of the vehicle. Shinhwa Auto USA utilizes state-of-the-art technology and stringent quality control to produce high-precision brackets that provide unwavering, perfect support even under the most extreme conditions.

Our brackets are more than just metal components; they are designed and manufactured to optimize the core functions of a vehicle.

Firmly connects major components to vehicle body, ensuring overall structural stability.

Maintains precise positions for aligned components, ensuring optimal function and performance.

Absorbs/isolates engine and road vibrations, minimizing transmission for a comfortable ride.

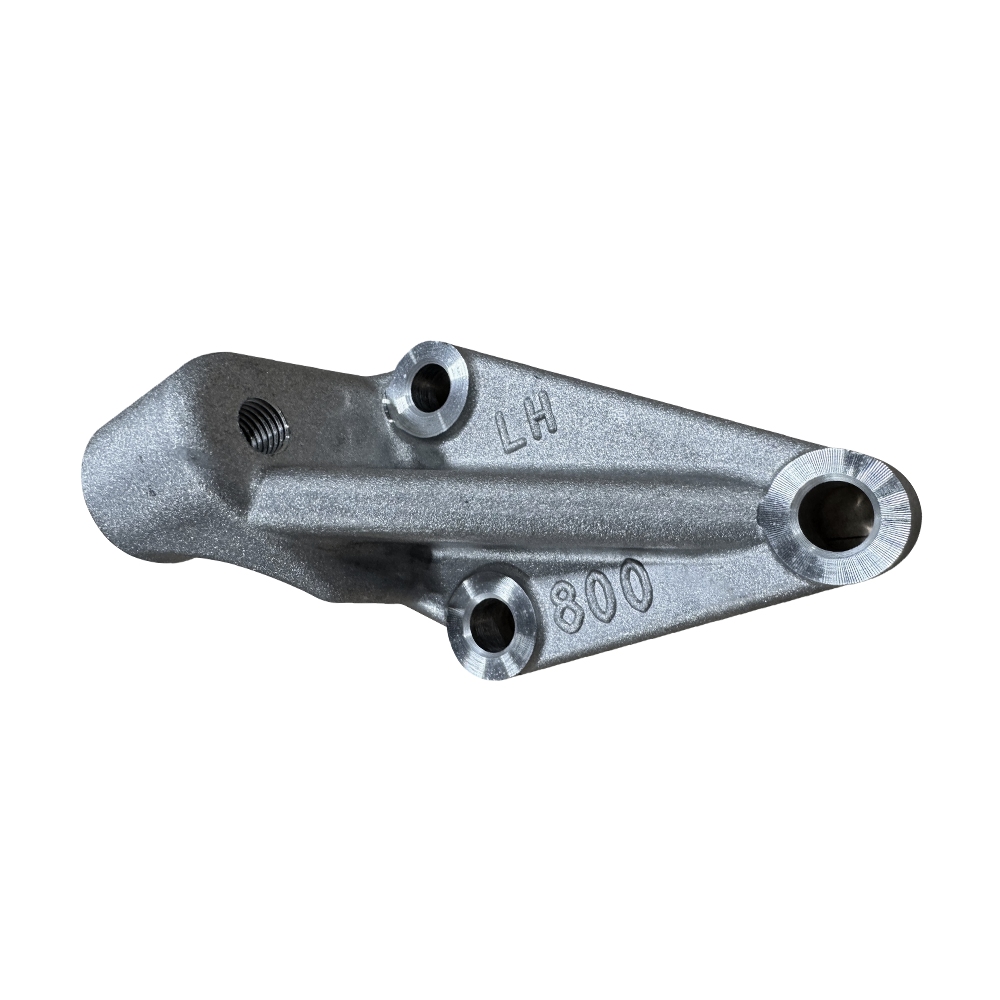

Shinhwa Auto USA’s Bracket Product Line: The Difference Solidness Makes

We design and produce brackets of various shapes and functions tailored to our clients’ specific requirements. Whatever your project needs, Shinhwa Auto USA is ready to provide the optimal solution.